The Power of Picoscope Automotive

WHAT IS PICOSCOPE AUTOMOTIVE?

The PicoScope 4425A is a high quality automotive oscilloscope designed for use in diagnosing and troubleshooting problems in modern vehicles. One of the primary uses of the PicoScope 4425A is for vehicle diagnostics. When a vehicle is experiencing issues with its engine, transmission, airbags, ABS, or other systems, mechanics use this tool to determine the root of the problem.

WHY IT IS ONE OF MY FAVORITE TOOLS

The Picoscope is an incredibly valuable diagnostic tool used in modern-day automotive diagnostics. Enabling me to perform thorough analyses of vehicles without simply guessing or replacing parts until the problem is solved. With its highly sophisticated diagnostic capabilities, the Picoscope can be thought of as an x-ray machine for your car. Allowing mechanics to easily test any electrical circuit and identify any issues that may be present.

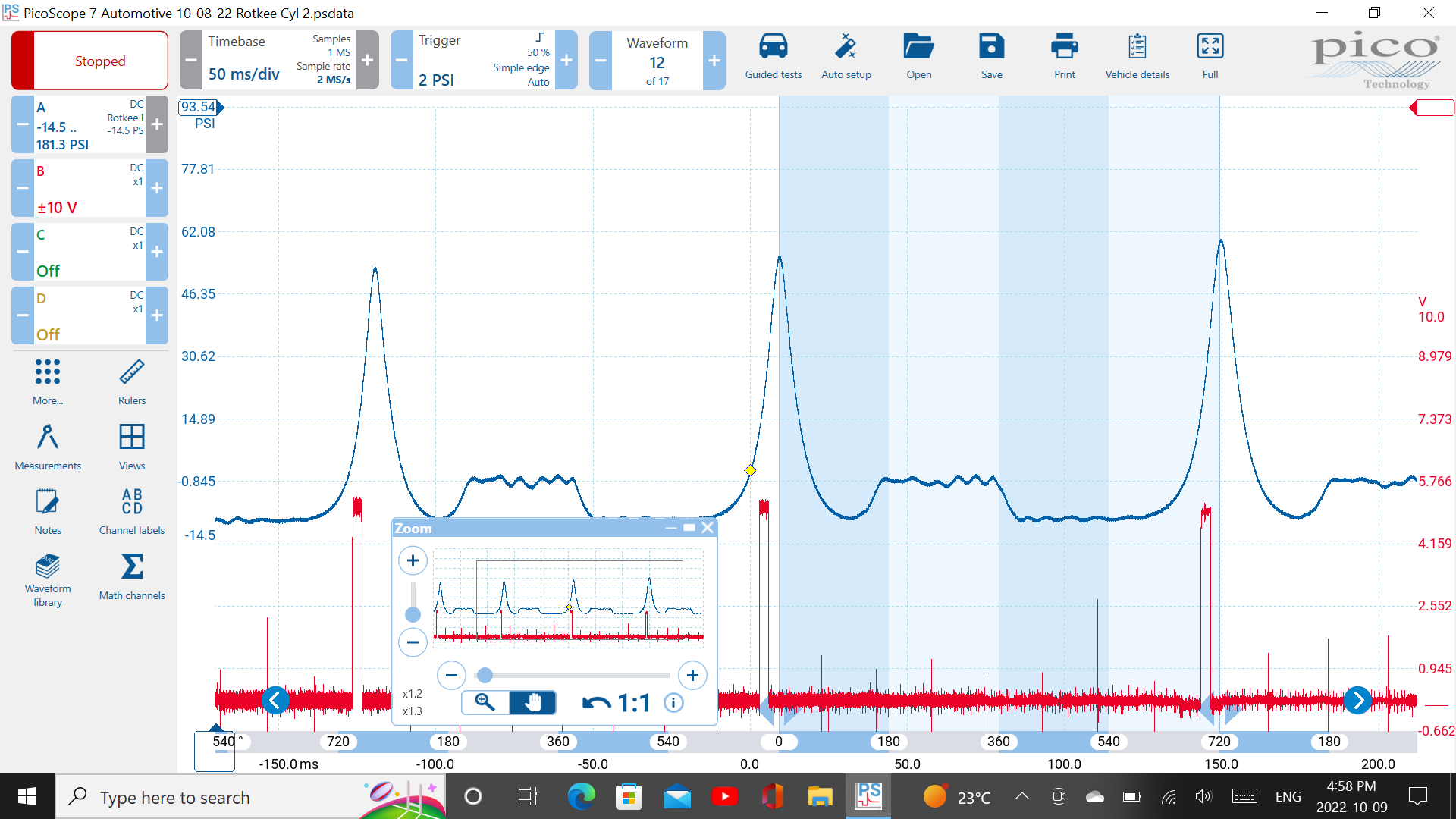

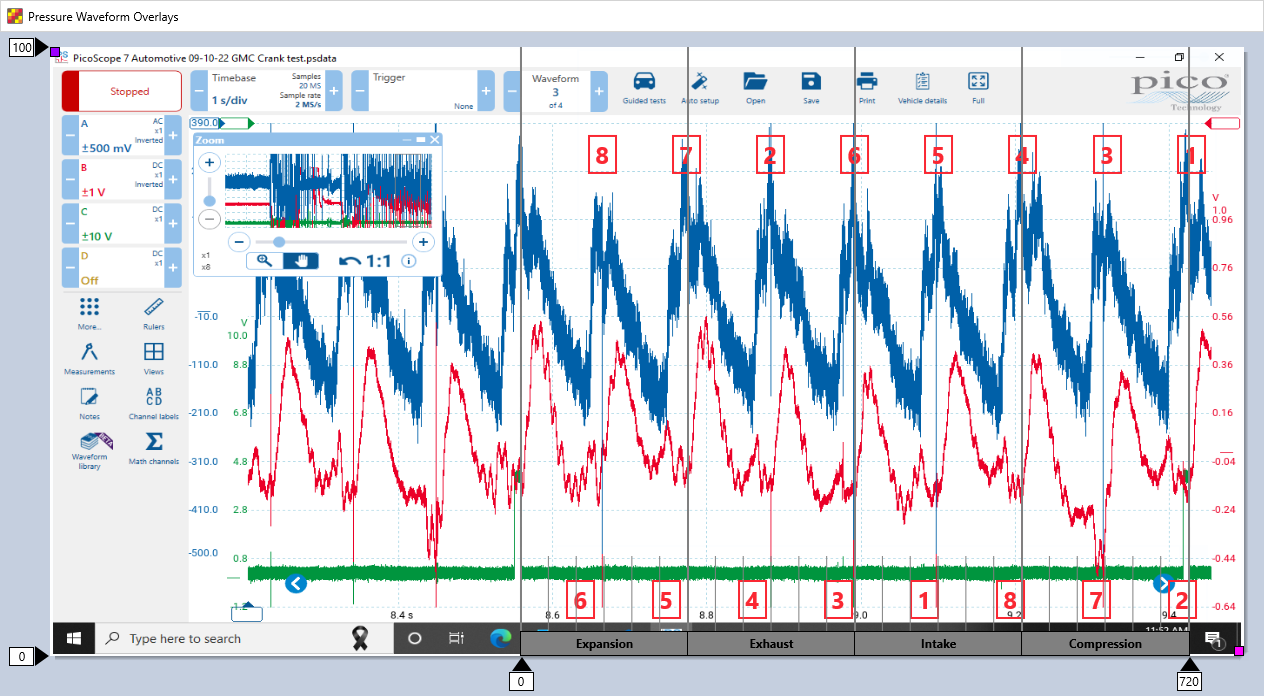

By combining data from the Picoscope with input from a pressure transducer placed in the spark plug hole, I can observe and analyze compression, cam timing, valve movement, and exhaust restrictions in real-time. This allows for a level of precision that simply cannot be achieved through guesswork or traditional diagnostic techniques.

Investing in a Picoscope can be a game-changer. Not only does it save time and improve accuracy. It also enables mechanics to diagnose and resolve issues that would otherwise go undetected. As cars continue to become more complex, some problems may develop that may not be visible without the use and training of advanced diagnostic tools like the Picoscope.

In my experience, the Picoscope has proven to be an invaluable addition to my toolkit. Providing a highly accurate and detailed view of vehicle systems and components. It enables me to diagnose and repair issues with greater speed and precision than ever before. As such, it is no surprise that many automotive shops are investing in this technology. In order to provide their customers with the highest level of quality of service possible.

TOP 10 USES:

- Ignition system testing: analyzing signals produced by ignition system components to diagnose issues with misfires, poor performance, and weak sparks.

- Fuel injection system testing: analyzing fuel injector signals to diagnose issues with fuel delivery and engine performance.

- Compression testing: using a pressure transducer to measure cylinder compression and identify issues with engine performance.

- Camshaft and crankshaft position sensor testing: analyzing signals produced by these sensors to diagnose issues with engine timing and performance.

- Alternator and battery testing: analyzing electrical signals produced by the alternator and battery to diagnose issues with charging and power delivery.

- ABS and stability control system testing: analyzing signals produced by these systems to diagnose issues with braking and stability control.

- CAN bus testing: analyzing signals transmitted over the CAN bus to diagnose issues with communication between vehicle systems and modules.

- Airbag system testing: analyzing signals produced by the airbag system to diagnose issues with airbag deployment and safety.

- Sensor testing: analyzing signals produced by various sensors, such as oxygen sensors and throttle position sensors, to diagnose issues with engine performance.

- HVAC system analysis: Picoscope can be used to analyze the performance of the HVAC system. Including temperature sensors, blower motors, and compressor operation, to diagnose issues with system performance or component failure.

HOW IT SAVES YOU MONEY:

By utilizing equipment such the Picoscope during diagnostic procedures, it is possible to identify the root cause of a problem quickly and accurately. This means that we can avoid the guesswork that often leads to unnecessary and costly repairs. Instead, I can focus on addressing the specific component or issue that is causing the problem, resulting in a more efficient and cost-effective repair process.

The Picoscope’s ability to provide detailed visual data helps mechanics to identify problems that may not be immediately visible. This data enables me to make informed decisions about the best course of action, rather than relying on trial and error. By accurately identifying the root cause of the problem, the Picoscope helps avoid replacing parts that are not actually causing the issue.

In summary, using the Picoscope during diagnostic procedures can help us avoid unnecessary repairs, reduce costs for vehicle owners, and improve the overall efficiency of managing the repair process. Keep money in your pocket from un-necessary parts replacement and time on labour. Contact us to find out more.